The Polini Thor 250, known for its strong thrust and dependable performance, has become a favoured choice among paramotor enthusiasts. However, like any complex engine, it can present occasional mechanical issues. For owners with a Capacitor Discharge Ignition (CDI) system, certain challenges may be more common. These “Polini Thor 250 CDI problems” can manifest in various ways, including difficult hot starts, misfires, and irregular idle. According to reports from experienced users, symptoms of CDI trouble can disrupt performance and reliability. Thus, knowing how to manage “Polini Thor 250 CDI problems” can significantly improve engine consistency, making flights smoother and more enjoyable.

To assist with this, we’ve compiled practical troubleshooting tips to address and prevent Polini Thor 250 CDI problems. Regularly checking the spark plug for wear, ensuring tight connections, and inspecting for signs of corrosion can prevent many issues before they worsen. Testing the CDI unit periodically and using high-quality fuel may also improve its reliability. By following these recommendations, you can minimise “Polini Thor 250 CDI problems” and enjoy a more seamless and dependable paramotor experience.

Understanding the CDI System: Why It Powers Polini Thor 250 Engines Efficiently

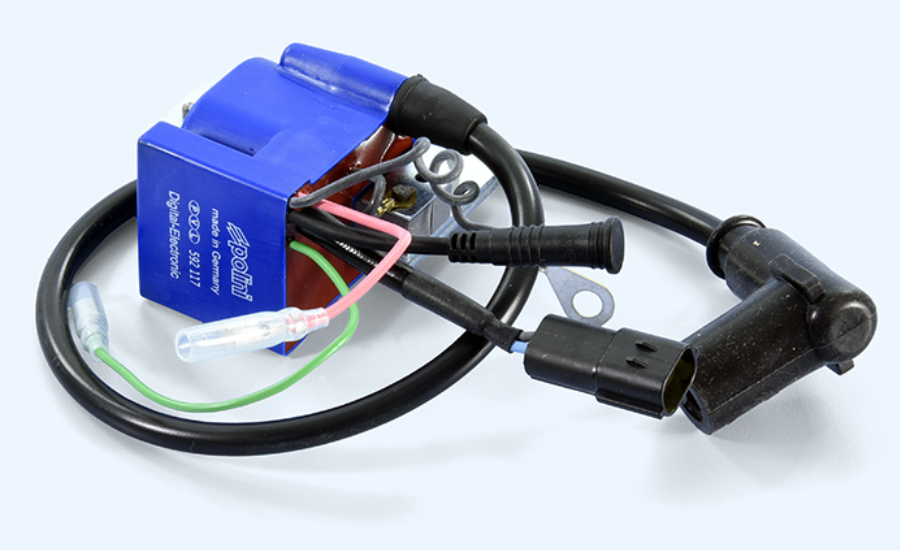

The CDI, or Capacitor Discharge Ignition, system is vital in engines like the Polini Thor 250. It stores energy in a capacitor, then releases it as a powerful spark for fuel ignition. This spark initiates the engine’s combustion cycle, making the system effective for high-speed and high-performance needs. The ignition coil works alongside the combustion engine to generate consistent sparks, ensuring smooth performance and quick starts. For paramotor engines, the CDI system is a preferred choice due to its reliability, precision, and efficiency under various conditions.

However, understanding the CDI can be challenging, especially for beginners or those unfamiliar with electrical components. Every tool and component serves a specific role, often requiring knowledge of electrical systems to troubleshoot. For first-time users, terms and functions might seem complex. Learning the basics of the CDI system, such as how each part interacts and why the spark is necessary, will ease any confusion.

Key Indicators Your Polini Thor 250 CDI Unit Needs Maintenance

Several signs can indicate a potential CDI failure in your Polini Thor 250, including difficulty starting or cranking, random power loss, and rough running. Misfires, erratic idle sounds, inconsistent engine speeds, and an unresponsive accelerator are also telltale signs. If you encounter these issues, the CDI unit in your Polini Thor 250 may be the culprit. Here’s a closer look at how to identify and address these problems to ensure smooth performance and reliability.

Step 1: Inspect CDI Connections

Loose or corroded electrical connections are often the main culprits behind CDI issues. The wires connecting to the CDI unit should be thoroughly inspected for any signs of wear, such as chewing or corrosion, which can hinder proper electrical contact. If you find any wires that are damaged or worn out, replacing them will be essential. To check these connections, you can use a multimeter to assess the continuity of the armature and the power supply to the CDI unit. If you encounter low or inconsistent voltage readings, typically around 25 volts, along with whirring noises, it indicates potential wiring faults. For resolution, clean the connectors with a dry cloth to remove any corrosion, tighten loose connections, and replace any damaged wires as needed. Additionally, improper grounding can significantly affect CDI functionality, leading to erratic engine behavior. It’s important to ensure that all grounding points are secure and free from rust. If necessary, clean or relocate these grounding connections to restore proper function.

Step 2: Evaluate the Ignition Coil

An ignition coil that is not functioning properly can easily be mistaken for issues related to the CDI, as its main role is to boost the voltage sent by the CDI to the spark plug. If the ignition coil is weak, it can produce a weak spark, leading to poor engine performance. To diagnose the ignition coil, use a multimeter to measure both the primary and secondary resistance of the coil. Refer to the Polini Thor 250 manual for the correct resistance values. If the coil does not meet these specifications, it will need to be replaced to ensure optimal engine performance.

Step 3: Inspect the Spark Plug

A fouled or damaged spark plug can significantly hinder engine performance, preventing proper starts or causing misfires, even when both the CDI and ignition coil are functioning correctly. This issue often arises from improper combustion, resulting in carbon buildup or a damaged electrode that impairs the spark plug’s ability to create a spark. To diagnose the problem, carefully remove the spark plug and examine it for signs of carbon deposits, oil accumulation, or physical damage. If the spark plug appears dirty, it can be cleaned and reinstalled; however, if it is cracked or excessively fouled, replacing it is necessary to restore optimal engine function.

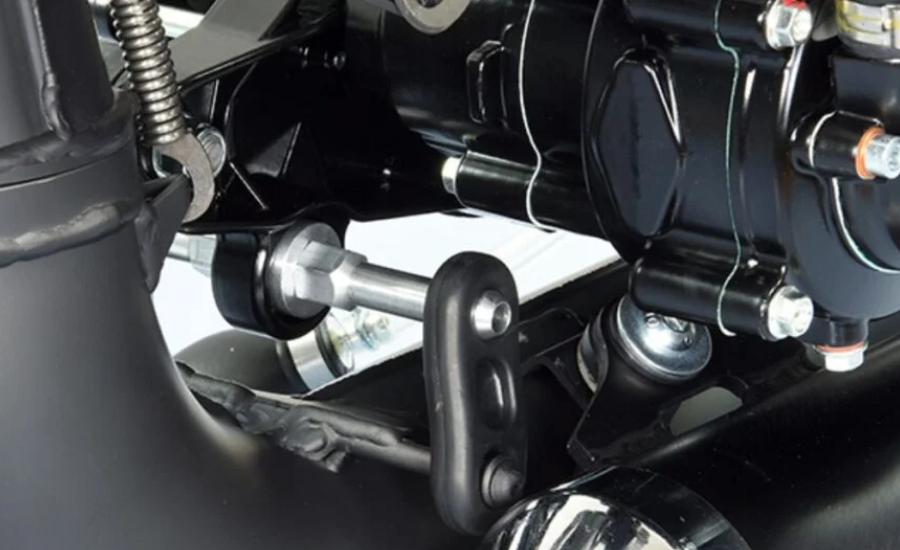

Step 4: Inspecting the Flywheel Magneto for Issues

The flywheel plays a crucial role in generating the electrical charge necessary for the Capacitor Discharge Ignition (CDI) system through its interaction with the ignition components. If the flywheel key shears or breaks, it can lead to misaligned timing, which may result in engine misfires or failure to ignite altogether. To diagnose this issue, you should carefully remove the flywheel cover and examine the flywheel key for any signs of wear or misalignment. If you notice any damage, replacing the flywheel key is essential to restore proper engine function.

Step 5: Testing the CDI Box for Faults

If all other components appear to be functioning normally, the CDI box itself may be the source of the problem. Internal wear and tear, excessive heat, or moisture exposure can lead to malfunctions within the CDI unit. To perform a proper check, locate the original CDI unit and assess whether its internal circuitry is functioning correctly and generating the necessary sparks. If you cannot ascertain the issue through visual inspection, replacing the CDI box with a known functional unit may be necessary to diagnose the problem effectively. Should the CDI box fail the test, it must be replaced to ensure reliable operation.

Step 6: Examining Engine Timing for Accuracy

The CDI system operates optimally when the engine timing is set correctly. If the timing is off, you may experience ignition issues, including difficulties in starting the engine and occasional misfiring. To verify the timing settings, refer to the Polini Thor 250 service manual for the correct timing marks and conduct a timing check using a timing light. Adhering to the manual’s guidelines is crucial for restoring the specified timing, ensuring that the CDI system can function as intended and improve overall engine performance.

Step 7: Investigating Overheating Issues with the CDI

Overheating is a common problem that can affect the CDI unit in the Polini Thor 250, particularly when the engine runs for extended periods. Excessive heat can lead to malfunctions or degradation of internal components within the CDI. To check for overheating, touch the CDI unit once the engine has started to assess its temperature. If the unit feels excessively hot or shows signs of smoking, it’s vital to implement cooling solutions to prevent future issues. Ensuring proper engine cooling and considering a heat shield or relocating the CDI unit away from heat sources can help mitigate these problems.

Additional Maintenance Tips for the Polini Thor 250 CDI System

Most issues related to CDIs can be resolved through adjustments in practices and regular maintenance. Here are some effective ways to ensure that your engine’s ignition system is operating at its best:

First, check all electrical connections: It’s essential to clean the connectors regularly and apply dielectric grease to prevent oxidation of the terminals. This simple step can significantly enhance the reliability of your CDI system.

Next, pay attention to the spark plug gap: Always ensure that the gap between the electrodes is properly set. This will help avoid any switching problems and promote efficient engine performance.

Lastly, monitor the engine temperature closely: Preventing overheating is crucial, so ensure proper airflow and be quick to respond to any cooling system issues. By maintaining these practices, you can enhance the longevity and functionality of your Polini Thor 250 CDI system.

Common Causes of Polini Thor 250 CDI Problems: Prevention and Solutions

Water and moisture can severely affect the functionality of CDI units, as exposure to these elements often leads to short circuits and damage to internal components. To prevent Polini Thor 250 CDI problems, it’s crucial to ensure that the CDI unit and its wiring are properly sealed against moisture.Vibrations over time can also contribute to connection issues, causing wires to become loose. To mitigate this risk, it’s advisable to use vibration dampeners and regularly check all fasteners for tightness.Furthermore, high temperatures can lead to CDI burnout if the unit is subjected to prolonged heat without adequate breaks. Proper ventilation around the engine area is essential, and installing a heat sensor gauge can help monitor temperature levels, providing an added layer of protection against potential Polini Thor 250 CDI problems.

Looking for Expert Assistance

If you’ve exhausted all troubleshooting options and the problem persists, it may be wise to consult a qualified technician specialising in paramotor engines. These experts utilise advanced diagnostic tools to identify underlying issues that might not be apparent during a basic inspection. Their experience and specialised equipment can help pinpoint the exact causes of the problems, ensuring a thorough and accurate assessment that leads to effective solutions. Seeking professional assistance can save time and prevent further complications, allowing you to get back to enjoying your paramotor with confidence.

Criteria for Choosing Replacement Parts

If you discover any defective components during the troubleshooting process, it is crucial to use only original or high-quality aftermarket parts specifically designed for the Polini Thor 250 engine when making replacements. Opting for low-quality parts can lead to recurring issues and prevent the engine from operating as intended. By investing in reliable components, you ensure the longevity and optimal performance of your engine, ultimately providing a smoother and more enjoyable experience while flying. Always prioritize quality over cost when selecting replacement parts to avoid potential setbacks and maintain the functionality of your Polini Thor 250.

FAQs About Polini Thor 250 CDI Problems

Q1. What are common symptoms of Polini Thor 250 CDI problems?

A. Common symptoms include difficulty starting, engine misfires, irregular idle, power loss, and an unresponsive accelerator.

Q2. How can I troubleshoot CDI issues in my Polini Thor 250?

A. Troubleshooting involves checking electrical connections, inspecting the ignition coil, examining the spark plug, and testing the CDI unit for faults.

Q3. What role does the CDI system play in the Polini Thor 250 engine? The A. CDI system is crucial for storing electrical energy and providing a powerful spark for ignition, ensuring efficient engine performance.

Q4. How can I prevent CDI problems in my Polini Thor 250?

A. Regular maintenance, such as inspecting connections, monitoring spark plug gaps, and ensuring proper engine cooling, can help prevent CDI issues.

Q5. When should I seek professional help for CDI problems?

A. If troubleshooting fails to resolve the issue, consulting a qualified technician can help diagnose deeper problems and ensure effective solutions.

Conclusion

In conclusion, the Polini Thor 250 engine has established itself as a reliable and powerful option for paramotor enthusiasts, yet it is not without its challenges, particularly concerning the Capacitor Discharge Ignition (CDI) system. Awareness of potential CDI problems, such as difficult hot starts, misfires, and irregular idle, is essential for maintaining optimal engine performance. By implementing regular maintenance practices—including checking electrical connections, inspecting the ignition coil and spark plug, and testing the CDI unit—owners can effectively mitigate these issues and enhance the longevity of their engines. Furthermore, understanding the CDI system’s crucial role in ignition and combustion can simplify troubleshooting for users at all experience levels. Should difficulties persist despite thorough inspection and maintenance, seeking professional assistance from a technician can provide the necessary expertise to resolve underlying issues. Ultimately, investing in high-quality parts and adhering to maintenance guidelines will ensure a smoother and more enjoyable paramotor experience, allowing enthusiasts to fully appreciate the capabilities of the Polini Thor 250.

Stay In Touch For More Updates And Alerts: Wales Buzz